Why do we need a metal jacket gasket?

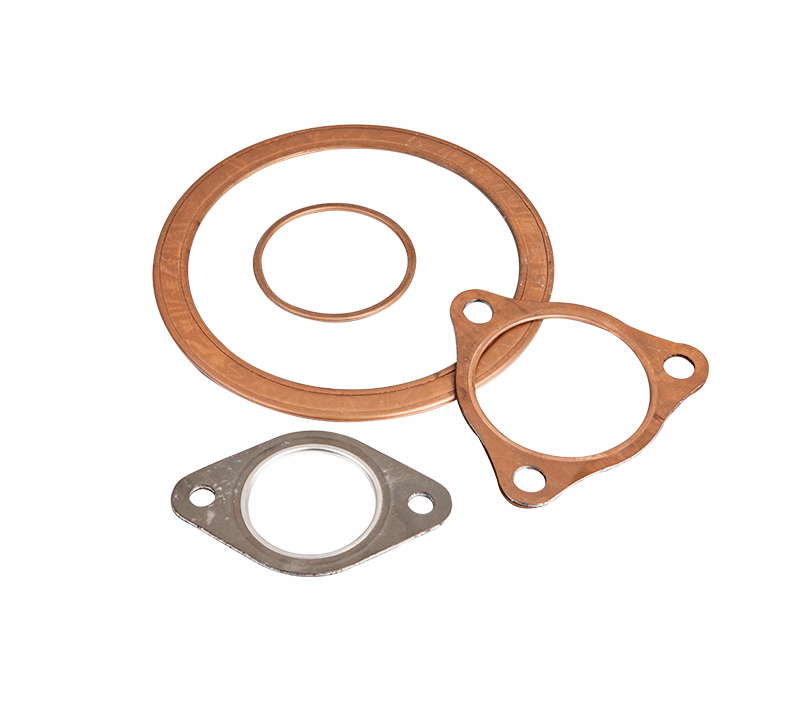

Have you dealt with applications that require metal jacketed gaskets? While this technology may not be as ubiquitous as others, it certainly has a place in the sealed world. The construction of the jacketed gasket consists of soft filler material with an outer layer of metal wrapped. Typically, this is two-piece metal construction with a flat layer on a soft finish and a wrap on both sides to form a complete shell to encapsulate the filler.

These gaskets are used in high pressure and high-temperature applications where flange area is limited but rigid construction is required. They are also used in heavy-duty exhaust applications, heat exchangers, and pipe flange gasket connections. High pressure and high-temperature applications often require rigid shields to prevent bursting. Additionally, the sheath function protects the core layer from these conditions.

Compared with non-metallic gaskets, the properties of metal make the surface sealing quality of gaskets higher. Because of their natural resistance to extreme temperatures, pressures, and chemical exposure, metal gaskets are now widely used in medium and high-pressure applications. Metal washers are also used for high-temperature applications.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language