What are The Key Features and Benefits of Metal Jacketed Gaskets

Metal jacketed gaskets, also known as metal-clad gaskets or jacketed gaskets, are specialized sealing products used in high-pressure and high-temperature applications where standard gaskets may not provide sufficient sealing performance. They are designed to withstand extreme conditions and provide effective sealing against leakage in demanding industrial environments.

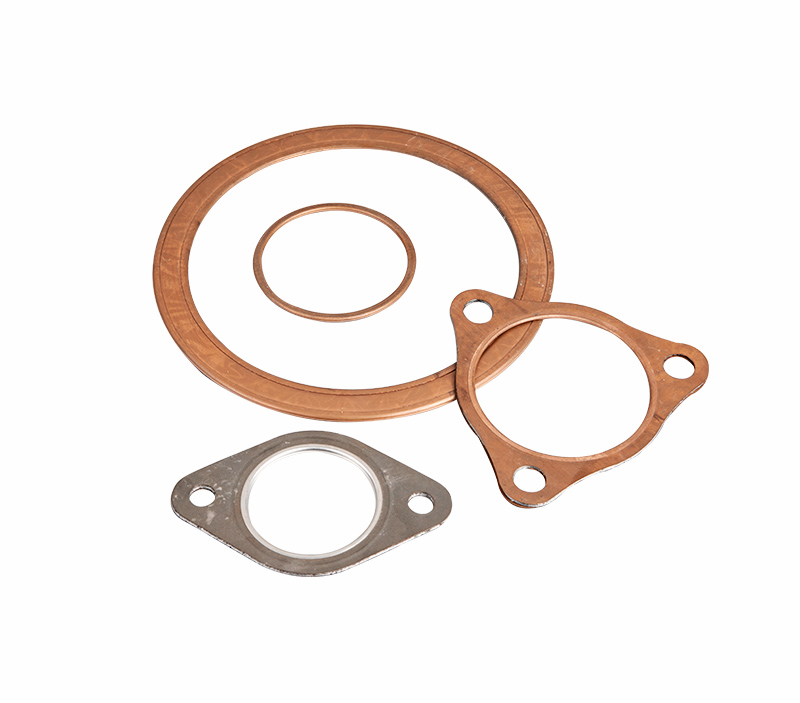

Structure and Construction:

Metal jacketed gaskets typically consist of a soft filler material, such as graphite, PTFE (polytetrafluoroethylene), or non-asbestos materials, enclosed by a metal jacket. The soft filler material provides the sealing properties, while the metal jacket adds strength, stability, and protection to the gasket. The metal jacket can be made of various metals, including stainless steel, carbon steel, or other alloys, depending on the specific application requirements.

Key Features and Benefits of Metal Jacketed Gaskets:

High Pressure and Temperature Resistance: Metal jacketed gaskets are designed to withstand high pressures and temperatures, making them suitable for applications in industries such as oil and gas, chemical processing, power generation, and petrochemicals. The metal jacket provides structural integrity and prevents the gasket from being crushed or deformed under extreme operating conditions.

Excellent Sealing Performance: Metal jacketed gaskets offer superior sealing performance, even in challenging environments where flanges may have surface imperfections or irregularities. The combination of the soft filler material and the metal jacket creates a reliable and resilient seal, minimizing the risk of leakage.

Chemical Compatibility: Metal jacketed gaskets are resistant to a wide range of chemicals, acids, and solvents, making them suitable for applications involving corrosive media. The choice of filler material and metal jacket can be tailored to provide optimal chemical resistance based on the specific process conditions.

Durability and Longevity: The metal jacket adds durability and protection to the gasket, extending its lifespan and reducing the need for frequent replacement. The metal jacket also provides resistance against mechanical damage, abrasion, and wear, enhancing the gasket's longevity and performance.

Metal Double Jacket Gasket is a composite gasket with internal nonmetal material such as flexible graphite, Teflon, asbestos-rubber sheet and ceramic fiber which is clad by special meta sheet in cold work. Proper medium, pressure and temperature are decided by different materials we use. The highest temperature is 1300"C and the highest pressure is up to 100Mpa.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language