What are the key advantages of rubber gaskets

Rubber gaskets play a crucial role in providing effective sealing solutions in a wide range of industries and applications. These versatile components are designed to create a secure and leak-proof seal between two surfaces, preventing the escape or entry of fluids, gases, or contaminants. With their flexibility, resilience, and chemical resistance, rubber gaskets are widely used in industries such as automotive, manufacturing, aerospace, plumbing, and more.

One of the key advantages of rubber gaskets is their flexibility. Rubber materials, such as neoprene, EPDM (ethylene propylene diene monomer), silicone, or natural rubber, offer excellent flexibility and elasticity. This allows rubber gaskets to conform to irregular or uneven surfaces, ensuring a tight and reliable seal. The flexibility of rubber gaskets enables them to adapt to changes in temperature, pressure, or mechanical stress, maintaining their sealing performance even in dynamic or challenging environments.

Rubber gaskets are known for their resilience and compression properties. When compressed between two surfaces, rubber gaskets exert a controlled amount of force to create a seal. This ability to maintain their shape and compression set over time ensures the longevity and effectiveness of the sealing solution. Rubber gaskets can withstand repeated cycles of compression and decompression without compromising their sealing performance, making them suitable for applications that require frequent assembly or disassembly.

Chemical resistance is another notable feature of rubber gaskets. Different rubber materials exhibit varying degrees of resistance to chemicals, oils, solvents, and other substances. This makes rubber gaskets suitable for sealing applications that involve contact with aggressive or corrosive media. For instance, certain rubber gaskets with high chemical resistance are used in chemical processing plants, oil refineries, or automotive applications where exposure to various fluids is common. It is important to select the appropriate rubber material based on the specific chemical compatibility requirements of the application.

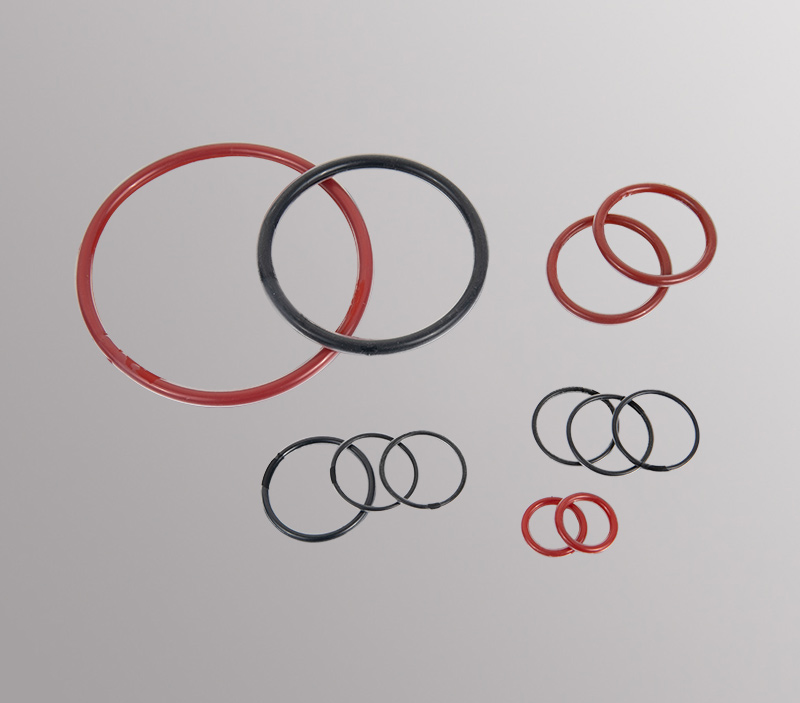

Versatility is a significant advantage of rubber gaskets. They are available in various shapes, sizes, and configurations to suit different sealing needs. Common types include O-rings, grommets, flange gaskets, diaphragms, and custom-molded gaskets. Rubber gaskets can be manufactured using different processes, such as compression molding, injection molding, or extrusion, allowing for customization and precise specifications. This versatility ensures that rubber gaskets can be used in a wide range of industries and applications, providing effective sealing solutions for diverse requirements.

Pure PTFE gasket made by cutting PTFE stick, pipe and sheet into flat shape PTFE gasket,v shape PTFE gasket or valve annulus PTFE gasket, it has 100% PTFE structure.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language