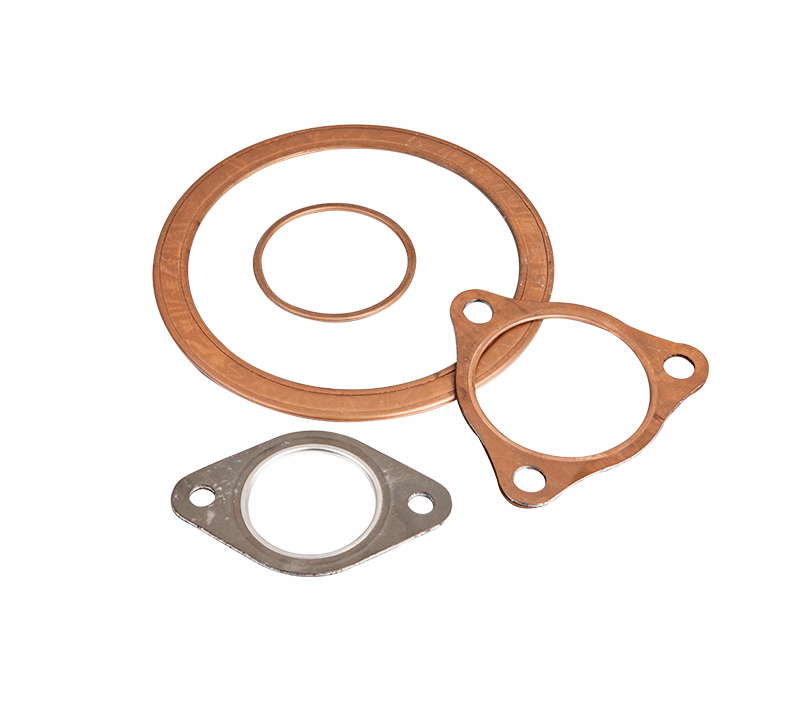

What are the features of metal jacketed gaskets

Metal jacketed gaskets are a type of gasket that combines the sealing properties of soft filler material with the structural strength and durability of a metal jacket. They are typically used in high-pressure and high-temperature applications in the oil and gas, petrochemical, and power generation industries.

Features of Metal Jacketed Gaskets

Metal Jacket: Metal jacketed gaskets have a metal outer layer that provides structural strength and durability to the gasket. The metal jacket is typically made of stainless steel, carbon steel, or other high-strength alloys.

Filler Material: The filler material used in metal jacketed gaskets can be a variety of soft materials, including graphite, PTFE, and ceramic. These materials provide the sealing properties of the gasket.

Corrosion Resistance: The metal jacket provides excellent corrosion resistance, making metal jacketed gaskets ideal for use in harsh environments.

High-Pressure and High-Temperature Resistance: Metal jacketed gaskets are designed to withstand high pressures and temperatures, making them suitable for use in a wide range of applications.

Benefits of Using Metal Jacketed Gaskets

High-Quality Sealing: The combination of a metal jacket and a soft filler material provides an effective and long-lasting seal that is resistant to leaks and blowouts.

Durability: Metal jacketed gaskets are highly durable and can withstand high pressures, temperatures, and harsh environments without losing their sealing properties.

Customizable: Metal jacketed gaskets can be customized to meet the specific needs of different applications, including different sizes, shapes, and materials.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language