What are the advantages of rubber gaskets?

Elasticity, or the ability to deform, is a key property of rubber that allows it to form a tight seal. Rubber gaskets are also easier to process and can be formulated from different raw materials. Following are some advantages of rubber gaskets.

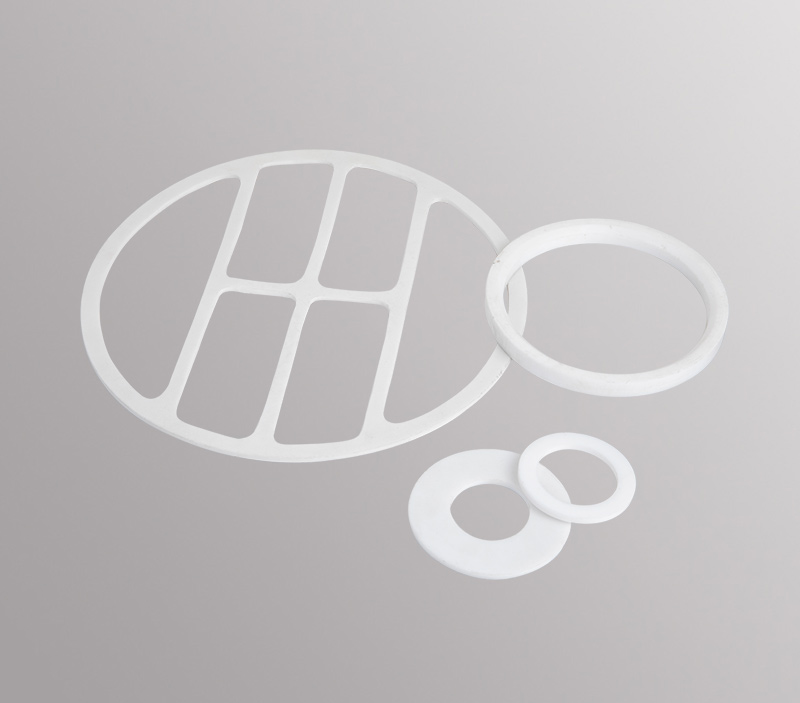

Cheap and easy to manufacture. Rubber gaskets are manufactured by combining raw rubber and additive materials and molding them into the desired profile. Rubber, like any other polymer, has excellent formability. In the liquid or uncured state, rubber, whether thermoset or thermoplastic, flows easily into the mold. Once hardened or cured, the material can be easily cut or machined to near-perfect dimensions. Rubber gaskets require lower heat and pressure to produce than metallic and other non-metallic gasket types. Hence, cheaper tools are used and lower operating costs are involved.

Excellent sealing performance. Due to its unique microstructure, rubber can be stretched or compressed without damaging or reducing its properties. This allows rubber gaskets to form effective seals, as they easily deform according to the surface of the part they are sealing. They form a more effective seal than some metal gaskets, which rely on grooves, and serrated or corrugated surfaces that create a labyrinth effect. Metal gaskets also exhibit some degree of deformation, but the seal is still metal-to-metal.

Every application has a different material type. Unlike other gasket types, there is a degree of flexibility and freedom in selecting the appropriate material for a particular application. This is due to the nature of producing elastic materials. Raw materials Elastomer raw materials such as synthetic rubber can be made from different hydrocarbons. After this raw material is produced, its properties are further modified by different additives such as stabilizers, fillers, antioxidants, and reinforcements. This design flexibility allows for the production of countless engineered rubber gasket materials, most of which are patented by major manufacturers.

Resistant to chemical attack and degradation. Rubber gaskets are a very stable material when used within their specifications. They are resistant to various chemical and environmental attacks such as acids, alkalis, oxygen, ozone, water, heat, and ultraviolet rays. Of course, it all depends on the type of rubber and compounding additives. Gaskets made from fluorocarbon-based elastomers provide excellent corrosion resistance. Examples include FKM and PTFE. Other materials with good chemical and aging resistance are SBR, Butyl, and EPDM.

Rubber gaskets offer several advantages, but others: a wide range of physical properties, can be cut or shaped into custom profiles, and are suitable for food-grade applications. Rubber gaskets offer several advantages over metallic and other non-metallic gaskets due to their unique set of properties.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language