What are the advantages of metal jacketed gaskets

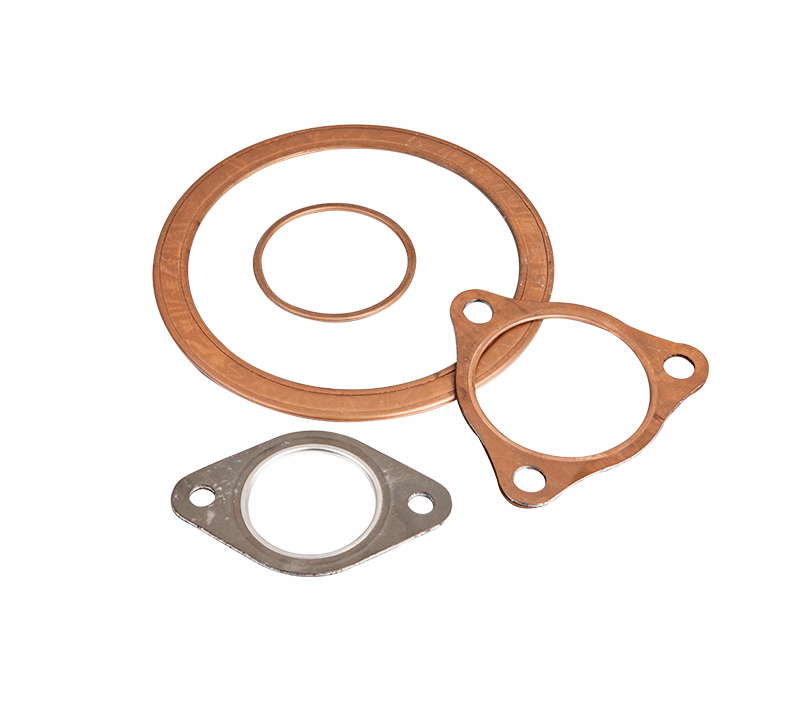

Metal jacketed gaskets are a type of sealing solution that consists of soft filler material, such as graphite or PTFE, encased in a metal jacket. The metal jacket provides structural support and helps to prevent damage to the gasket during installation and use. Metal jacketed gaskets offer a range of advantages over other types of gasket materials.

One of the key advantages of metal jacketed gaskets is their high temperature and pressure resistance. They are designed to withstand extreme conditions, such as high temperature and pressure fluctuations, making them an ideal choice for applications that require a reliable and durable sealing solution.

Another advantage of metal jacketed gaskets is their excellent chemical resistance. They are resistant to a wide range of chemicals, including acids, alkalis, and solvents, which makes them suitable for use in harsh and corrosive environments.

Metal jacketed gaskets are also highly versatile and can be used in a variety of applications, including oil and gas, chemical processing, and power generation. They are suitable for use in both static and dynamic applications and can be customized to fit a wide range of shapes and sizes.

Metal jacketed gaskets are also easy to install and maintain. They require minimal compression, which makes them easy to install, and they do not require any additional sealants or adhesives. They can also be reused multiple times, which helps to reduce costs and minimize waste.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language