The functions and types of hydraulic seals

Hydraulic seals are critical components used in hydraulic systems to prevent fluid leakage and maintain the efficiency and reliability of the system. These seals play a vital role in creating a tight barrier between moving parts, ensuring proper fluid containment and preventing contamination.

Function and Importance of Hydraulic Seals:

Hydraulic seals are designed to contain hydraulic fluids within the system, preventing leakage and maintaining the necessary pressure levels. They create a reliable barrier between different components, such as cylinders, pistons, and valves, ensuring proper operation and minimizing energy loss. Hydraulic seals also protect the system from external contaminants, such as dirt, dust, and moisture, which can cause damage and reduce the system's overall efficiency.

Types of Hydraulic Seals:

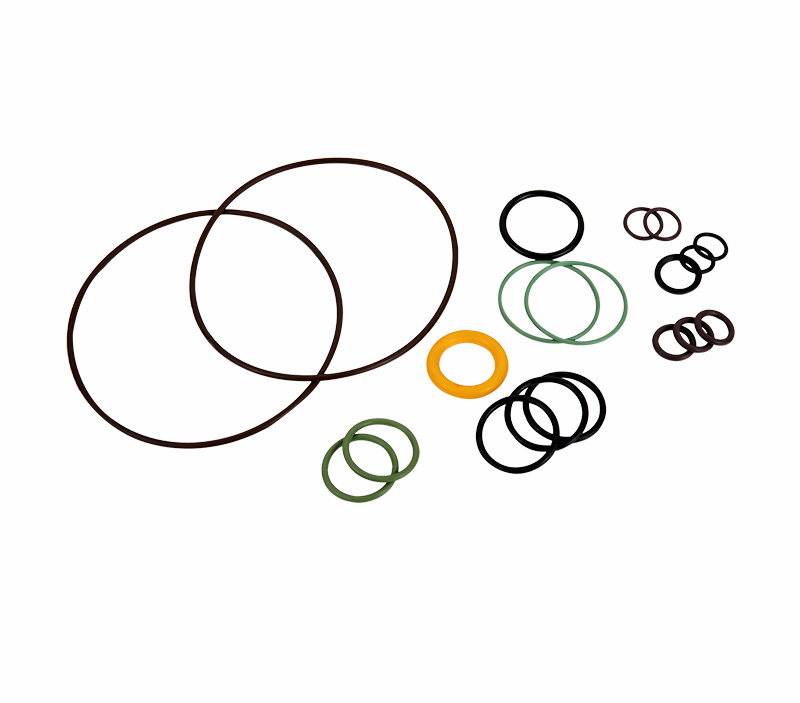

There are various types of hydraulic seals available, each designed to suit specific applications and operating conditions. Common types include piston seals, rod seals, wiper seals, and O-rings. Piston seals are used to seal the piston against the cylinder wall, while rod seals prevent fluid leakage along the piston rod. Wiper seals protect the system from external contaminants, and O-rings are versatile seals used in a wide range of hydraulic components.

Materials and Design Considerations:

Hydraulic seals are manufactured from different materials, depending on the specific requirements of the application. Common materials include nitrile rubber, polyurethane, silicone, and fluorocarbon. The material selection is influenced by factors such as temperature, pressure, fluid compatibility, and the presence of external contaminants. Additionally, the design of hydraulic seals takes into account factors like seal lip geometry, lubrication requirements, and the presence of backup rings or guide rings to enhance performance and extend the seal's lifespan.

Application Considerations:

Hydraulic seals find applications in various industries, including automotive, construction, manufacturing, and aerospace. They are used in hydraulic cylinders, pumps, valves, and other hydraulic components. The selection of hydraulic seals depends on the specific operating conditions, fluid compatibility, temperature ranges, pressure levels, and the required lifespan of the seals. Consulting with seal manufacturers or experts can help ensure the appropriate seal selection for a specific application.

Rubber o-rings have good sealing performance, long service life. Its dynamic working life is 5-10 times higher than ordinary rubber products.

Under certain conditions , it owns the same service life as the basic sealing part.

We also can offer Rubber O Ring Kits SG-H5101.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language