The features and benefits of spiral wound gaskets

Spiral wound gaskets are essential sealing solutions widely used in industrial applications to ensure reliable and leak-free connections between flanged joints. With their ability to withstand high temperatures, pressures, and varying media, spiral wound gaskets provide effective sealing and contribute to the integrity and safety of industrial systems.

Construction and Design:

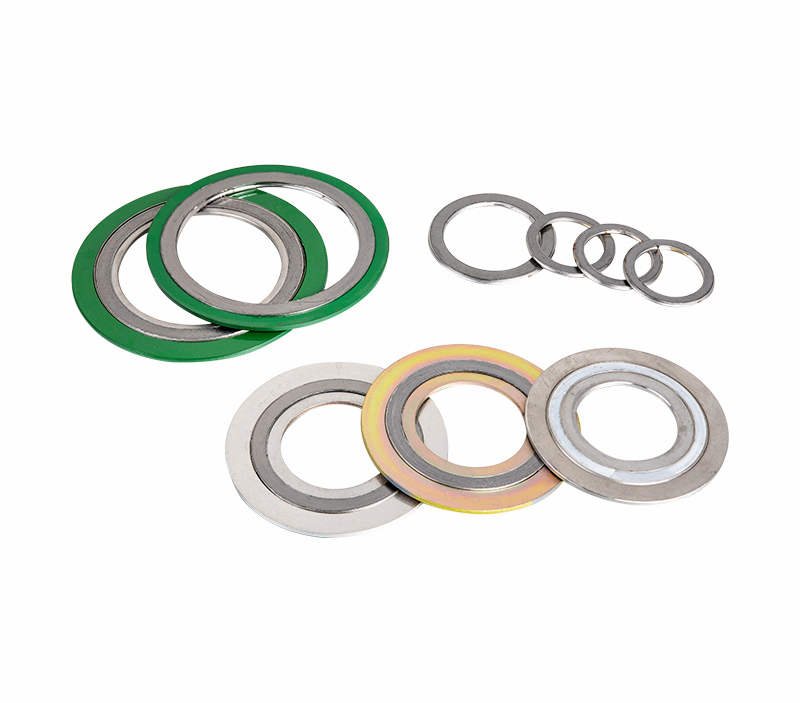

Spiral wound gaskets consist of alternating layers of metal winding and filler material. The metal winding typically includes stainless steel or other alloys, providing structural strength and resilience. The filler material, such as graphite or PTFE (polytetrafluoroethylene), acts as a sealing element, offering excellent resistance to chemicals, temperature variations, and compression.

The unique spiral configuration of the gasket allows it to adapt to flange irregularities, creating a tight and reliable seal. The inner and outer diameters of the gasket are reinforced with metal rings, enhancing stability and preventing blowouts during installation and operation.

Sealing Performance and Versatility:

Spiral wound gaskets are known for their exceptional sealing performance in demanding environments. The combination of metal winding and filler material provides excellent resilience, allowing the gasket to maintain a tight seal even under extreme conditions. The gaskets can effectively withstand high temperatures, pressure differentials, and aggressive media, making them suitable for use in various industries, including oil and gas, chemical processing, power generation, and petrochemical sectors.

The filler material in spiral wound gaskets offers excellent chemical resistance, preventing leakage and contamination. The gaskets can be customized with different filler materials to meet specific application requirements, ensuring compatibility with a wide range of media and operating conditions.

Installation and Maintenance:

Spiral wound gaskets are relatively easy to install and require minimal maintenance. The gaskets are available in various sizes and configurations to match different flange specifications. During installation, proper alignment and torque application are essential to achieve an effective seal.

Periodic inspection and replacement of spiral wound gaskets are recommended to ensure optimal sealing performance. However, with their durable construction and resistance to wear and tear, spiral wound gaskets offer extended service life and reduce the frequency of replacements, minimizing downtime and maintenance costs.

This gasket is wound altermatively by V or W shaped metal hoop and non-metal filler of various kinds of materials selected based on specific working condition.

Depend on its excellent compression resilient, high-temperature and corrosion resistance. It is suitable for sealing alteration of temperature and pressure are frequent, such as pipe, valve, pump etc. They are available in all standard flanges of sizes, such as ASME, JIS, DIN, EN. etc.

Spiral Wound Gasket Application

It is suitable for sealing flange joints, manhole and handhold covers, tube covers, boilers, heat exchangers, press vessels, pumps, compressors and valves; industries such as petrochemical, pharmaceutical, shipbuilding, and food processing, in power industries and nuclear power station. They are ideal for steam, oil, liquids, gases, acids, alkalines, various organic mediums and solvents.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language