The difference between asbestos and non-asbestos gaskets

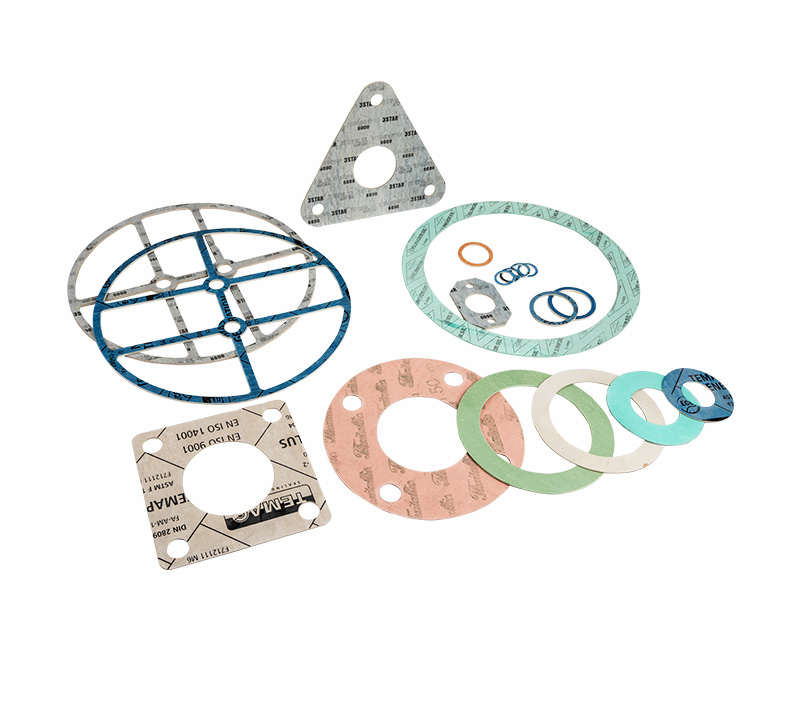

Gaskets are an important part of sealants used in various industrial applications. We offer non-asbestos gaskets to meet gasket specifications for many applications. Asbestos gaskets have been used in the industry for several years. Growing concerns about the health hazards of asbestos have led manufacturers to look for alternatives. Gasket manufacturers have introduced non-asbestos gaskets to ensure personnel safety during production.

Asbestos fibers are strong and can withstand high temperatures. These fibers are thin and long. Manufacturers of non-asbestos gaskets utilize materials such as graphite, Teflon, etc. as reinforcing fibers in gaskets. These fibers have properties such as heat resistance, chemical resistance, and temperature resistance. The properties of these fibers ensure that the performance of the gasket is not compromised by discontinuing the use of asbestos.

Asbestos gaskets are made of silicate fibers, while non-asbestos gaskets are made of carbon-based or organic materials. Asbestos gaskets are less expensive than non-asbestos gaskets. Gasket manufacturers have been using different materials to provide their customers with innovative and efficient non-asbestos gaskets that can be easily customized to their needs.

Non-asbestos gaskets are made from organic fibers, aramid fibers, nitrile rubber and mineral fibers. These can be used in applications that require water or oil repellency. Typically, non-asbestos gaskets are used in low voltage equipment, transformers and compressors. They are also used in valve covers and oil pans of internal combustion engines where deformable parts are present.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language