The benefits of using non-asbestos materials

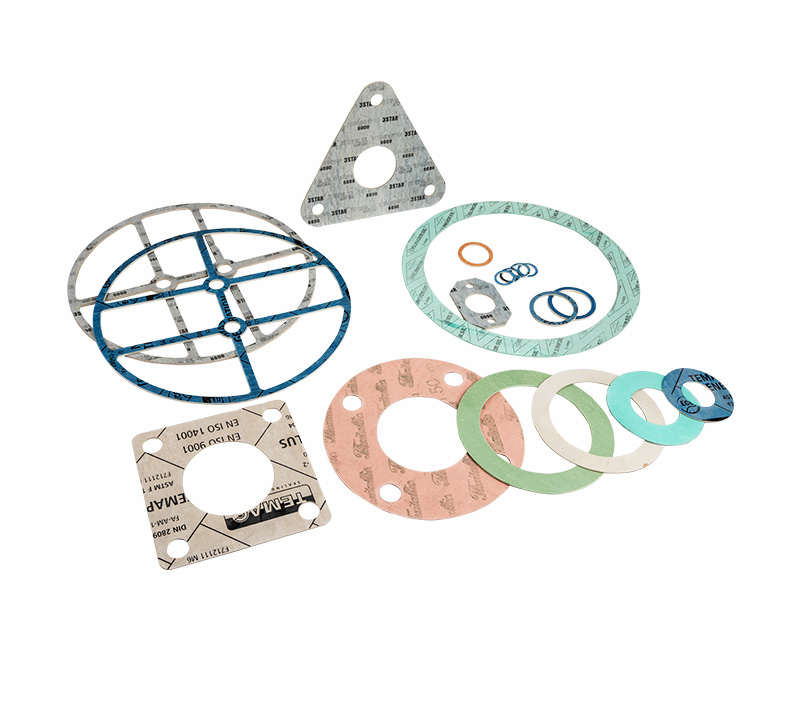

Non-asbestos fiber materials are called non-asbestos fiber materials because they fill a gap in the range of gasket materials previously occupied by asbestos. Although considered a hazardous material, asbestos has excellent heat resistance properties, which is why it is so widely used in high-temperature applications.

When asbestos is outlawed, the material needs to be replaced. Therefore, these non-asbestos or non-asbestos materials were developed to perform the same function without the corresponding problems. Non-asbestos materials generally have very good heat resistance.

They are also suitable for applications that expose them to water, gasoline, or natural gas. Therefore, non-asbestos materials are used in air compressors, diesel engines, pipelines, and many other general industrial and marine environments.

Non-asbestos materials are now usually composed of aramid fibers, carbon, and other non-organic fibers. These fibers are in turn blended with different polymers for different applications, most commonly nitrile rubber for fuel and oil resistance.

These materials can also be coated with graphite for non-stick and steam resistance, blended with PTFE for excellent chemical resistance or blended with EPDM for potable water applications.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language