Ring Joint Gaskets Are Mainly Used In The Petrochemical Industry

Ring Joint Gaskets are solid metal gaskets that are highly polished and softer than flange materials. The gasket is actually "crushed" into a flange (embossed and in close contact), and a seal is formed by filling the defect and leakage path with the gasket material. Under high sealing stress, the gasket will deform, but the flange will not.

Ring Joint Gaskets are mainly used in the petrochemical industry (offshore oil platforms, oil refineries) because their processes require high service pressure.

Ring Joint Gaskets are precisely designed and processed to meet strict specifications and strict tolerances (ASME B16.20, API 6A).

Handling and storage

It is important to use the correct packaging, handling, and storage methods, because any bruises, gouges (dents, dents, etc.), or grooves on the seal contact area may prevent uniform imprinting and continuous close contact, resulting in damage Regional leaks. Any rough handling or impact contact on hard surfaces or objects may cause damage to the ring gasket, rendering it unusable. Soft iron and carbon steel ring gaskets must be kept dry to prevent rust and pitting.

The coating on these Ring Joint Gaskets will provide some rust protection in a short period of time, but long-term storage in a humid environment may destroy the usefulness of these gaskets. Stainless steel ring joint gaskets are more resistant to damp and humid conditions.

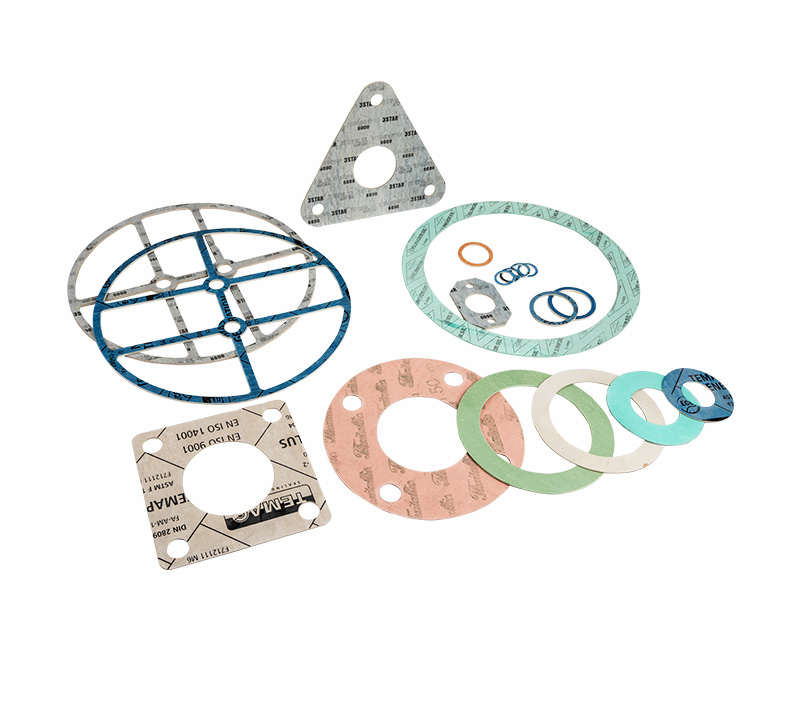

Non-Asbestos Gaskets is also our product, welcome to consult and purchase.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language