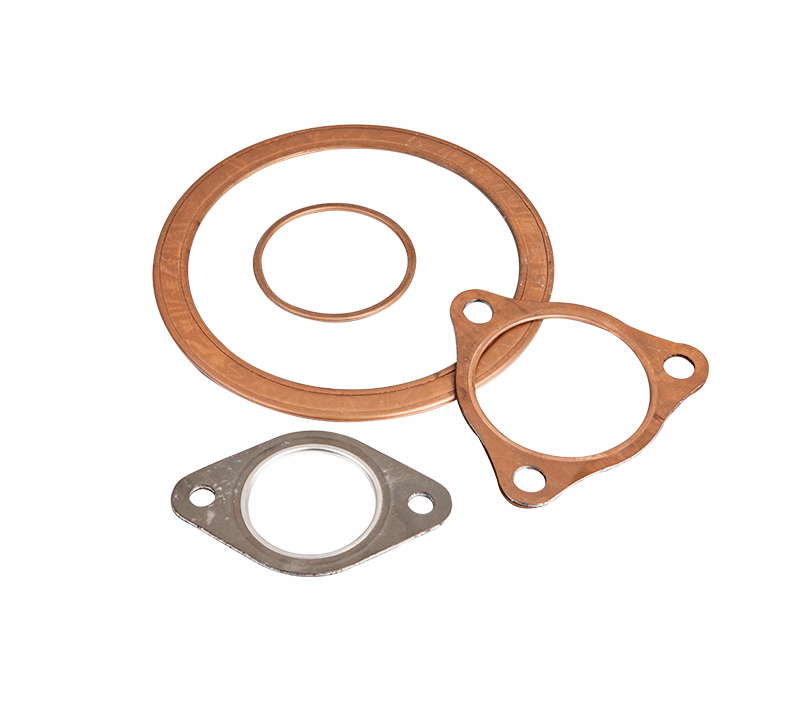

Metal Jacketed Gaskets Consist Of Thin Metal Shells

Metal Jacketed Gaskets consist of a thin metal shell with elastic filling material inside. The metal shell of Metal Jacketed Gaskets protects the elastic packing and is resistant to pressure, temperature and corrosion. Metal Jacketed Gaskets are handmade, with a variety of shapes and sizes to choose from, and a variety of metals and fillers to choose from. Internal ribs of any configuration can be provided.

Filling material: This is usually graphite, but PTFE, ceramic, and non-asbestos can also be used.

Sheath material: This is usually soft iron, SS316, SS304, brass, copper, Inconel, etc. These gaskets are widely used in heat exchanger applications but require a good and uniform flange surface and high bolt load to achieve sealing.

The single-jacket gasket has a surface, and the outer and inner diameters are covered by a metal jacket. They are suitable for narrow flange widths in low-pressure valve/pump applications.

The double-jacketed gasket is completely enclosed by a two-piece metal jacket, covering the outer diameter, inner diameter, and two sealing surfaces. They are widely used in heat exchanger applications and are suitable for corrosive and high-temperature services. The internal ribs (via the partition) can be integral or welded because, in both types, the primary seal is safely maintained

Spiral Wound Gaskets For Sale is also our product, welcome to consult and purchase.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language