High Performance Technology Of Spiral Wound Gaskets For Sale

Spiral wound gaskets for the power generation industry

In today's rapidly changing environment, the power generation industry has more choices than ever before. From natural gas, fossil fuels, coal, and nuclear power to hydroelectric power, wind power, solar power, and biomass energy, there are many ways to produce energy.

To withstand the extreme temperatures and conditions of these applications, manufacturers rely on durable gaskets and sealing solutions. Power plants require large amounts of land and resources to convert electricity on a large scale.

The gaskets used in these factories must be able to withstand a range of operating conditions and pressures in order to distribute power evenly over long distances.

The company's mission is to meet this demand while minimizing costs and strive to achieve the best efficiency and innovation.

At Gasket Resources Inc. (GRI), we aim to help power companies deal with the complexity of this evolving industry.

Our reliable gasket solutions enable the company to easily meet the needs of the communities it serves while maintaining a leading position in power generation trends.

Spiral Wound Gaskets For Sale: High-Performance Technology

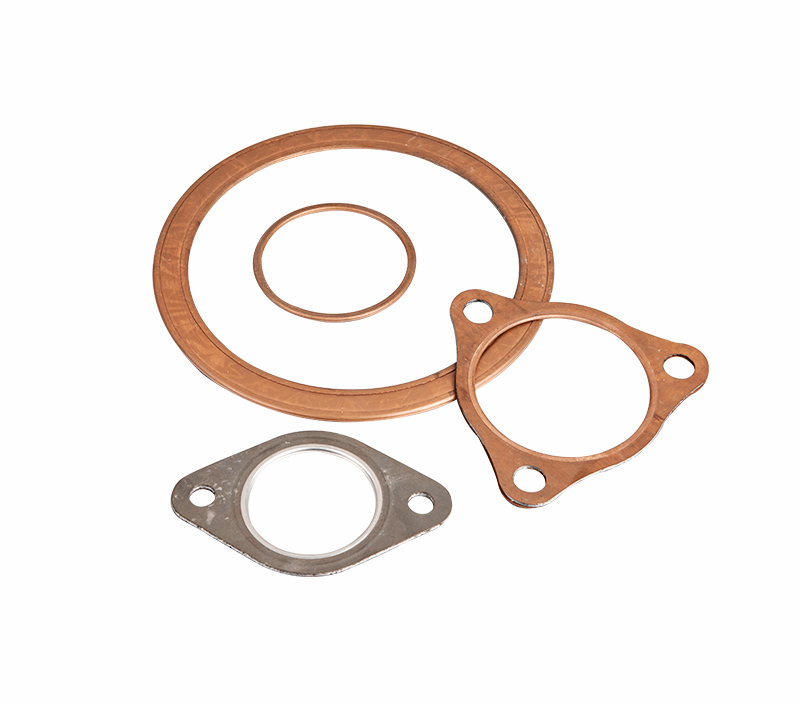

Metal Jacketed Gaskets Manufacturers' spiral wound gaskets (SWG) are manufactured in accordance with ASME B16.20 standards, and their quality assurance meets API Q1 specifications. They are ideal solutions for power generation industries ranging from natural gas to fossil fuels, circulating pumps, and even turbines.

SWG is made of a variety of smart materials: prefabricated metal strips alternate with more compressible soft filling materials, thus achieving a highly sensitive seal.

The engineering shape of the gasket metal band responds like a spring under load pressure, and even if the conditions change, the seal has high elasticity.

These special gaskets provide a variety of energy-saving options for various applications, including low-pressure turbines, condenser systems, boiler feed pumps, generators, jumper flanges, and lubricating oil systems.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language