Four Knitting Methods For Packing

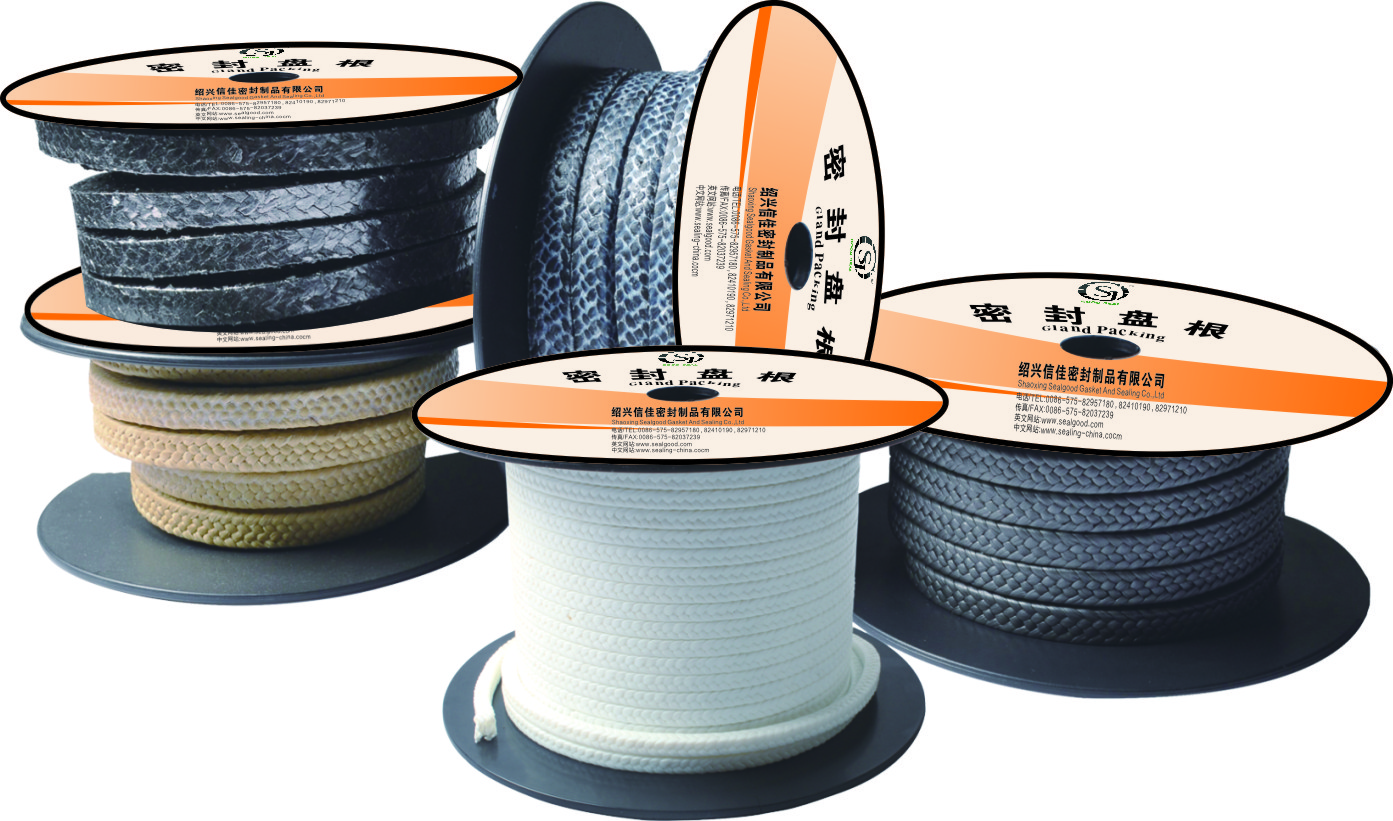

With the continuous emergence of production technology, the braided forms of fillers are gradually diversified. According to different use conditions and environments, different braided forms have a direct impact on the performance and service life of the seal. The main weaving forms of packing weaving fillers are: braid weaving, sheath weaving, core weaving, sandwich weaving and so on. The packing format and characteristics are as follows:

1. Braid braiding: braid braiding is running on two tracks with eight spindles. There are wool cores in the four corners and the middle. The section of the braided product is square, which is characterized by loose packing, but vibration and eccentricity. With a certain compensation effect, it is only used for small cross-section fillers, but large cross-sectional dimensions will cause the shortcomings of rough filler appearance, loose structure and poor compactness.

2. Sleeve knitting: Sleeve knitting is knitting on two tracks with 8, 12, 16, 24, 36, 48, 60 and other spindles. The cover is determined according to the specifications of the disk. Generally, 1-4 layers are woven, and there is no velvet in the middle. The core and jacket layer have good packing density and strong sealing. However, because it is a jacket layer, there is no fiber connection between the layers and it is easy to delaminate, so it is mostly used for static sealing or low-speed equipment.

3. Through-core weaving: The through-core weaving is knitted on three or four tracks with 8, 12, 16, 24, 36, 48, 60 and other spindles. The section is square, the surface is flat, elastic and abrasion resistant. Good, high strength, good compactness, the contact surface with the shaft is larger and uniform than the braid type, and the gap between the fibers is small, so the sealing performance is good, the entire filler will not be loose after the surface layer is worn, and the service life is long. It is a relatively advanced Woven structure.

4. Sandwich knitting: The sandwich knitting is a rubber or metal core, the fiber is outside, and the number of layers is set according to the needs. It is similar to the sheath knitting. The sandwich knitting has good sealing performance, high strength, and bending performance. Good, good sealing, but like the jacket structure, the surface layer is easy to fall off after being worn out. It is generally used for pumps and valves, and rarely used for reciprocating equipment.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language