Advantages of Non-Asbestos Gaskets

Non-Asbestos Gaskets are a type of gasket that is designed to provide a seal in applications where traditional asbestos-containing gaskets are not recommended. These gaskets are typically made from a combination of aramid fibers, mineral fibers, and other materials that are designed to mimic the properties of asbestos while being safe to handle and use.

Non-Asbestos Gaskets are commonly used in applications where there is a risk of exposure to asbestos, such as in the food processing, pharmaceutical, and medical industries. They are also used in applications where the gasket will be exposed to high temperatures and pressures, such as in power generation, oil and gas, and chemical processing industries.

One of the main advantages of Non-Asbestos Gaskets is that they are safer to handle and use than traditional asbestos-containing gaskets. Asbestos has been linked to serious health problems, including lung cancer and mesothelioma, and its use has been heavily regulated or banned in many countries. Non-Asbestos Gaskets are a safer alternative that can provide similar sealing performance without health risks.

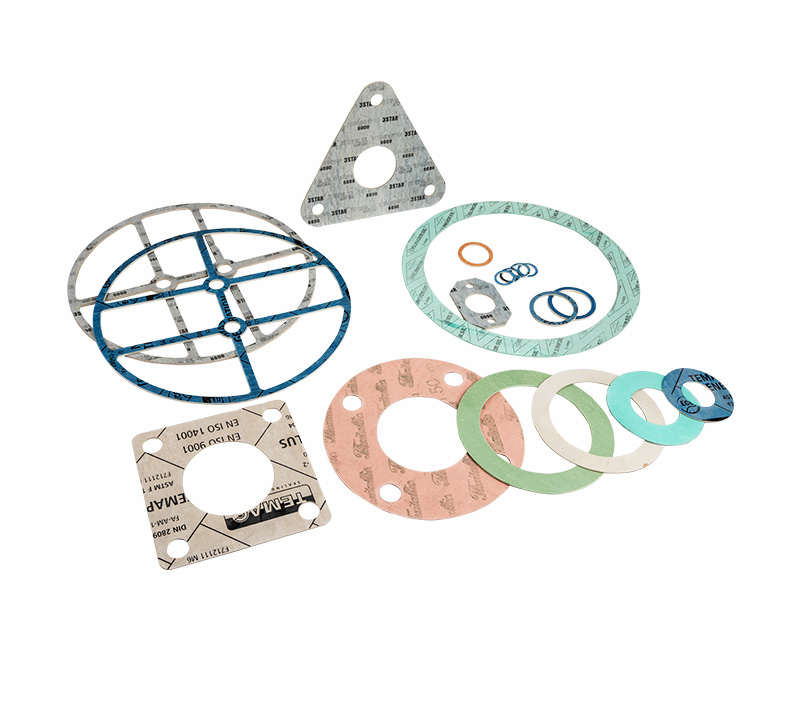

Non-Asbestos Gaskets come in a variety of forms, including sheet gaskets, spiral wound gaskets, and metal-jacketed gaskets. They are available in a range of thicknesses and materials to suit different applications and conditions. Some types of Non-Asbestos Gaskets are designed to be able to withstand high temperatures, pressures, and harsh chemicals, while others are intended for more general-purpose applications.

Overall, Non-Asbestos Gaskets are a safer alternative to traditional asbestos-containing gaskets and provide a reliable and effective sealing solution for a range of applications in a variety of industries.

English

English CHINESE

CHINESE Espana

Espana Arab

Arab Language

Language